Product Description

Imagine a box that keeps your medicine safe and sound. That’s basically what our Medicine Tuck End Box is all about. At Get Packaging Services, we make these boxes with care, making sure they are strong enough to protect what’s inside.

What It Is

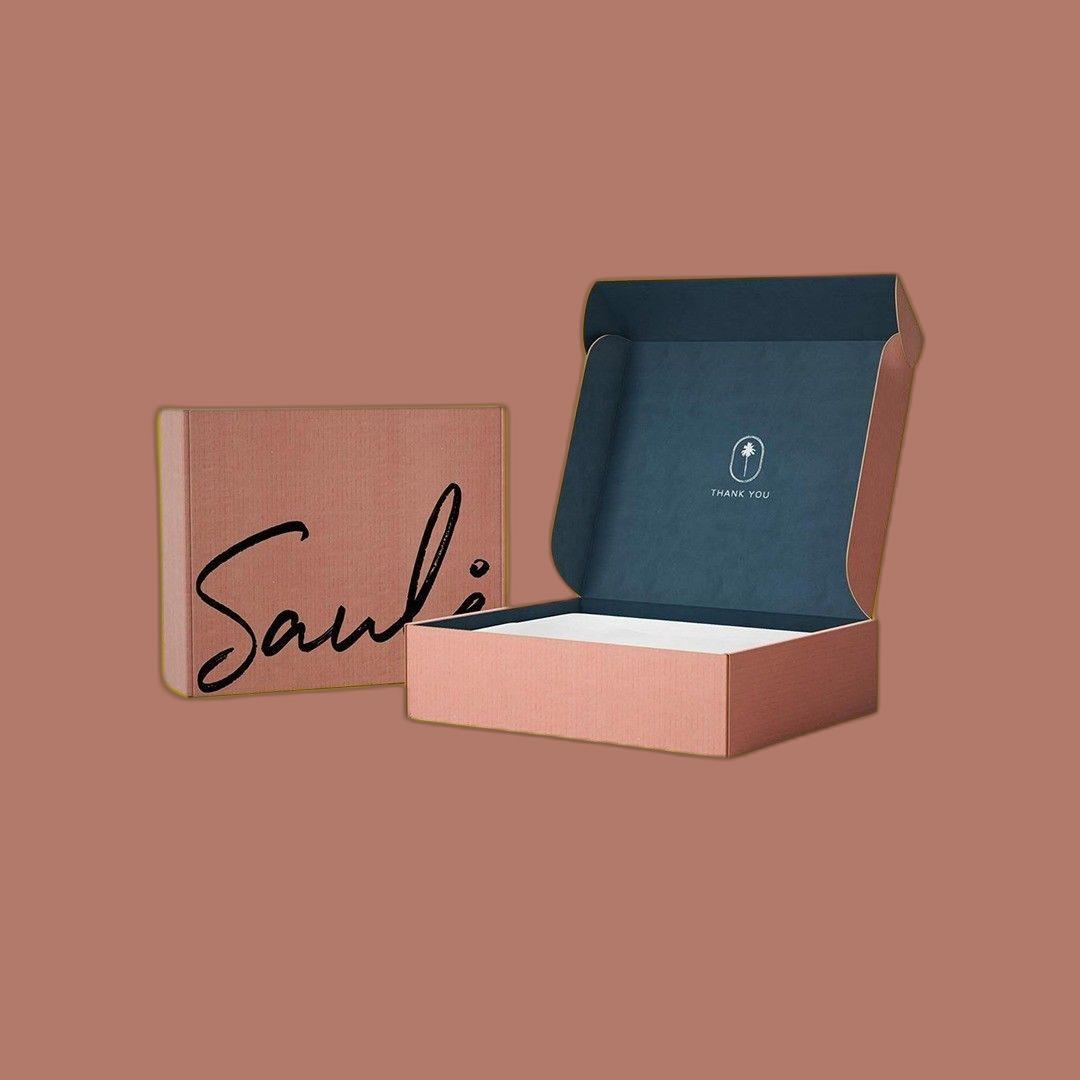

A Medicine Tuck End Box is a special type of box used to hold medicine bottles, pills, or even tubes of cream. It’s called a “tuck end” box because of how it closes. The flaps at the ends of the box fold in and tuck into each other, making a secure closure. Think of it like folding paper airplanes, where you tuck the paper into itself to make the point stay together. It is a simple but effective design.

Why It’s Good for Medicine

Medicine needs to be kept safe from all sorts of things. Light, moisture, and even just being bumped around can sometimes damage medicine. Our boxes are made from strong cardboard that helps protect against these dangers. The thick cardboard keeps light out, and the close fit of the tuck end helps keep moisture away. This protection helps ensure the medicine inside stays effective for longer. We also ensure the material used is safe and doesn’t react with the medicine inside. This is really important because you don’t want the packaging to ruin the medicine.

How It’s Made

First, we start with large sheets of cardboard. These sheets are made from paper that’s been pressed and glued together to make them strong. Then, a big machine cuts the cardboard into the right shape for the box. This shape is called a “die cut.” Think of it like using a cookie cutter to make cookies, but instead of cookies, we’re making cardboard boxes. After the box is cut, it’s folded and glued together. The glue has to be strong so the box doesn’t fall apart. Finally, the box is ready to be printed with information about the medicine.

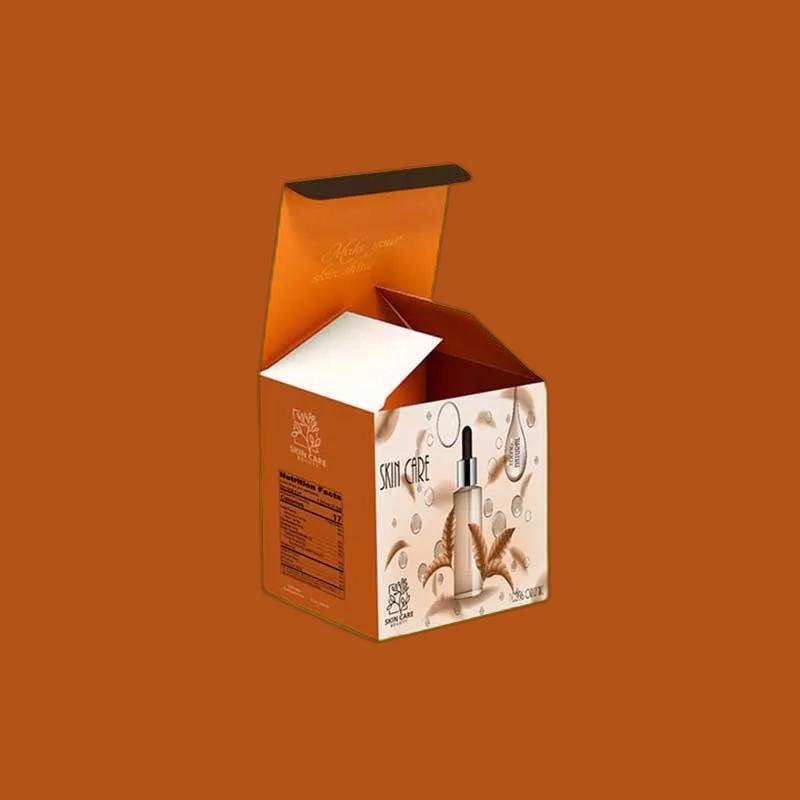

Printing and Labeling

The printing on the box is really important. It tells you what the medicine is, how to use it, and when it expires. This information helps people use the medicine correctly and safely. We use special inks that won’t fade or smudge easily. This ensures the information stays clear and readable. We can also print important warnings or instructions on the box, such as “Keep out of reach of children” or “Store in a cool, dry place.” The design of the printing can also help the medicine stand out on a shelf, making it easier for people to find.

Easy to Use

Even though the tuck end closure is secure, it’s also easy to open. You just need to gently pull the flaps apart. This is important because people need to be able to access their medicine quickly when they need it. The box is also easy to recycle after you’re finished with the medicine. Cardboard is a material that can be recycled and turned into new paper products, which helps the environment.

Different Sizes and Shapes

Medicines come in all sorts of shapes and sizes, so our boxes do too. We can make Medicine Tuck End Boxes to fit small bottles of pills, larger bottles of liquid medicine, or even tubes of cream. We can also customize the size and shape of the box to fit specific requirements. If a medicine needs a particularly strong box, we can use thicker cardboard. Or, if a medicine needs to be kept extra safe from light, we can use cardboard that has a special coating.

Why Choose Get Packaging Services

At Get Packaging Services, we understand how important it is to have reliable and safe packaging for medicine. We pay close attention to every detail, from the strength of the cardboard to the clarity of the printing. We work closely with our customers to make sure they get the exact boxes they need. We can also help with the design of the box, making sure it looks good and provides all the necessary information. Our goal is to provide high quality boxes at a fair price. We believe everyone deserves access to safe and reliable medicine packaging.

Environmentally Friendly

We care about the environment, so we try to use materials that are sustainable and recyclable. The cardboard we use is often made from recycled paper, and we encourage our customers to recycle the boxes after they’re finished with them. We are always looking for new ways to reduce our environmental impact. For example, we are exploring the use of plant based inks for printing, which are less harmful to the environment than traditional inks.

Perfect For

The Medicine Tuck End Box is perfect for pharmaceutical companies, pharmacies, and anyone who needs to package and protect medicine. It’s a simple, reliable, and cost effective solution for keeping medicine safe and secure. Whether you need to package a small batch of medicine or a large quantity, our boxes can get the job done right. We are committed to providing our customers with the best possible packaging solutions.

Our turnaround time is 8-10 working days. You may shop with us for as low as just 100 pieces. Moreover, your design customizations will be taken care of by our expert designers. You can consult with them to have the most amazing designs for your

Tuck Boxes. Our customer service is available 24/7. You can contact us via live chat, send us an email at

sales@getpackagingservices.com or simply call at 773 572 9034 for instant assistance.