Product Description

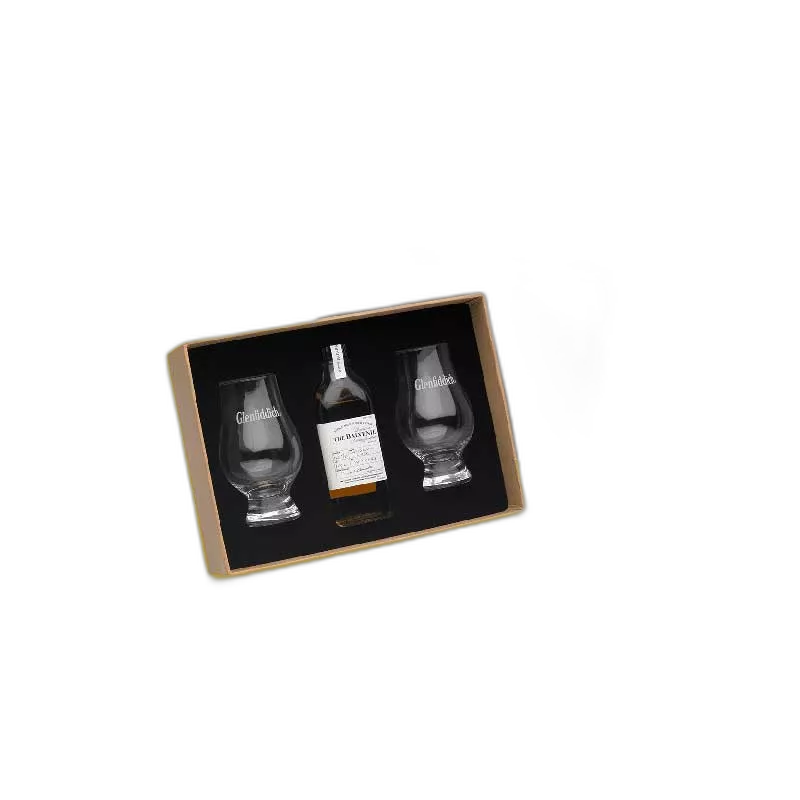

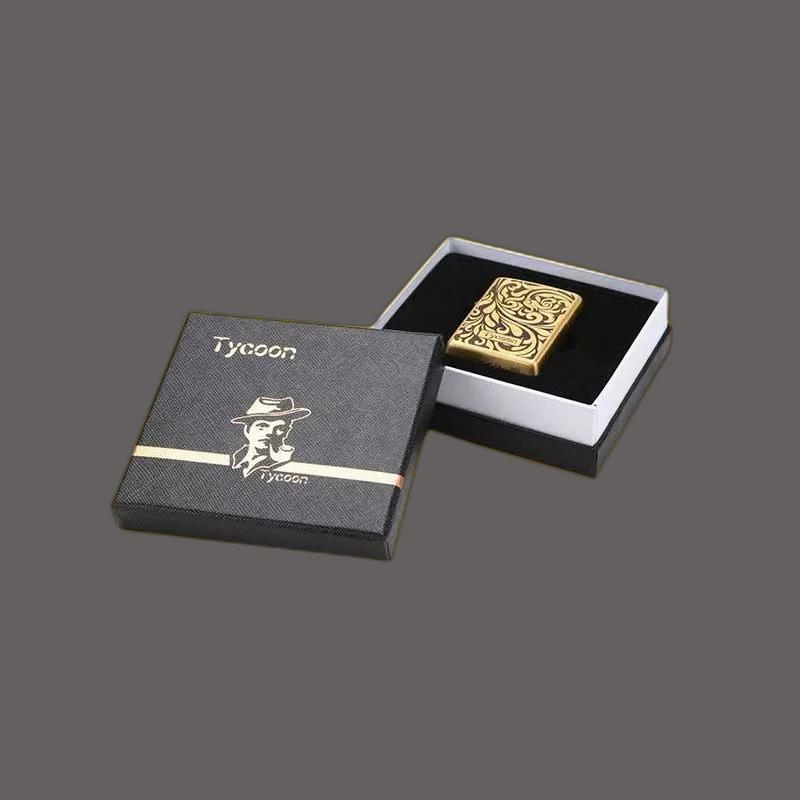

Imagine you have something really special. Maybe it’s a new video game console, a delicate camera, or a set of tools you use for your hobby. You wouldn’t just throw it in a box with some newspaper, right? You’d want to protect it. That’s where custom design foam inserts from Get Packaging Services come in. They’re like little beds of protection for your valuable items.

What are Custom Design Foam Inserts?

Think of foam inserts as puzzle pieces. They’re made from soft, squishy foam that we cut into specific shapes. These shapes are designed to perfectly fit your product. Instead of your item bouncing around inside a box, it sits snugly in its own custom made space. This keeps it safe from bumps, scratches, and even breaking during shipping or storage. We make them so your product fits just right. It’s like a custom made suit, but for your belongings.

Why Choose Foam Inserts from Get Packaging Services?

There are lots of reasons why using our foam inserts is a good idea. First, they provide excellent protection. Foam is good at absorbing shocks. If the box gets dropped, the foam cushions the impact and prevents damage to the item inside. Second, they look professional. When someone opens a box and sees their product neatly displayed in a custom foam insert, it gives them a good impression of your company. It shows you care about quality and presentation. Third, they’re versatile. We can create foam inserts for almost anything, regardless of size or shape. Whether it’s small electronic parts or heavy machinery components, we can make a foam insert that fits. Fourth, using foam inserts reduces damage, which saves you money in the long run. You’ll have fewer returns and fewer disappointed customers.

Different Types of Foam We Use

We use different types of foam, depending on what you need. Some foam is softer, perfect for delicate items. Other foam is denser and more rigid, for heavier or more fragile products. We’ll help you choose the best type of foam for your specific needs.

- Polyurethane Foam: This is a common type of foam. It’s lightweight and good for general protection. Think of it as a soft pillow for your product.

- Polyethylene Foam: This foam is denser and more rigid than polyurethane. It’s good for heavier items or items that need more support. It’s like a firm mattress, keeping your product stable.

- Anti Static Foam: Some electronic components are sensitive to static electricity. Anti static foam prevents static from building up and damaging the product. It is designed to protect electronics.

How to Order Custom Foam Inserts

Ordering custom foam inserts from Get Packaging Services is easy. First, tell us about your product. We need to know its dimensions (length, width, and height) and its weight. If you have a drawing or a sample of your product, that’s even better. Second, we’ll work with you to design the foam insert. We can create a computer model of the insert to make sure everything fits perfectly. Third, we’ll create a prototype, which is a sample insert. You can test it with your product to make sure it meets your needs. If you’re happy with the prototype, we’ll start production. Our experienced team will carefully cut the foam and create the inserts to your exact specifications. We will guide you during the process.

Benefits of Using Custom Foam Inserts

Let’s recap the good things about using custom foam inserts. Protection from damage is the most important. Foam absorbs impacts and prevents scratches and breakage. Professional appearance is also very important. Custom inserts make your product look high quality. Versatility means we can create inserts for almost any product. Cost savings result because less damage means fewer returns and replacements. Brand building is supported as custom inserts can be printed with your company logo or name. This makes your packaging more memorable and reinforces your brand identity. Ease of use helps as foam inserts are easy to load and unload. This saves time and effort in your packing process.

Get Packaging Services: Your Partner for Packaging Solutions

At Get Packaging Services, we’re more than just a foam insert provider. We’re your partner in creating packaging solutions that protect your products and enhance your brand. We’re committed to providing high quality products and excellent customer service. We work with you from start to finish to ensure you get the perfect foam inserts for your needs. Contact us today to learn more about our custom design foam inserts and how they can benefit your business. We’re here to help you protect what matters most.

Frequently Asked Questions

Here are some questions people often ask about our foam inserts:

- How much do custom foam inserts cost? The price depends on the size, complexity, and quantity of the inserts. Contact us for a free quote.

- How long does it take to get custom foam inserts? The turnaround time depends on the complexity of the design and the quantity ordered. We’ll give you an estimated delivery date when you place your order.

- Can you print on foam inserts? Yes, we can print your company logo or other designs on the foam inserts.

- What if I need to change the design? We’ll work with you to make any necessary changes to the design before we start production.

We believe in quality and customer satisfaction. Let Get Packaging Services help you design the perfect foam inserts for your products.

Our turnaround time is 8-10 working days. You may shop with us for as low as just 100 pieces. Moreover, your design customizations will be taken care of by our expert designers. You can consult with them to have the most amazing designs for your

Inserts Boxes. Our customer service is available 24/7. You can contact us via live chat, send us an email at

sales@getpackagingservices.com or simply call at 773 572 9034 for instant assistance.