Product Description

These boxes, called Corrugated Boxboard boxes, are the workhorses of the shipping world. They are the brown boxes you see everywhere, from the grocery store to your doorstep when something gets delivered. Get Packaging Services makes these boxes strong and reliable, so your stuff gets where it needs to go safely.

What is Corrugated Boxboard?

Corrugated boxboard is a special kind of cardboard. Think of it like a sandwich. It has two flat pieces of cardboard on the outside. Sandwiched in between those flat pieces is a wavy, fluted layer. This wavy layer is what gives the box its strength. That wavy part is called the “corrugated medium.” It’s like the ribs of a building, making the whole structure stronger. The flat outer layers are called “linerboard.”

The type of paper used to make corrugated boxboard comes from trees, but often it is made using recycled paper. Get Packaging Services is focused on using more recycled materials to help the environment. The corrugated medium is glued to the linerboard with a special adhesive. This creates a sturdy material that can withstand a lot of pressure and protect what’s inside.

Why Use Corrugated Boxboard Boxes?

These boxes are used for many different reasons. First, they are strong. The wavy layer inside the box helps it resist being crushed. This is very important when shipping things that could break easily. Second, they are lightweight. Even though they are strong, corrugated boxboard boxes don’t weigh much. This helps keep shipping costs down. Third, they are recyclable. Many corrugated boxboard boxes are made from recycled materials, and they can be recycled again after they are used. Get Packaging Services encourages recycling to help protect our planet.

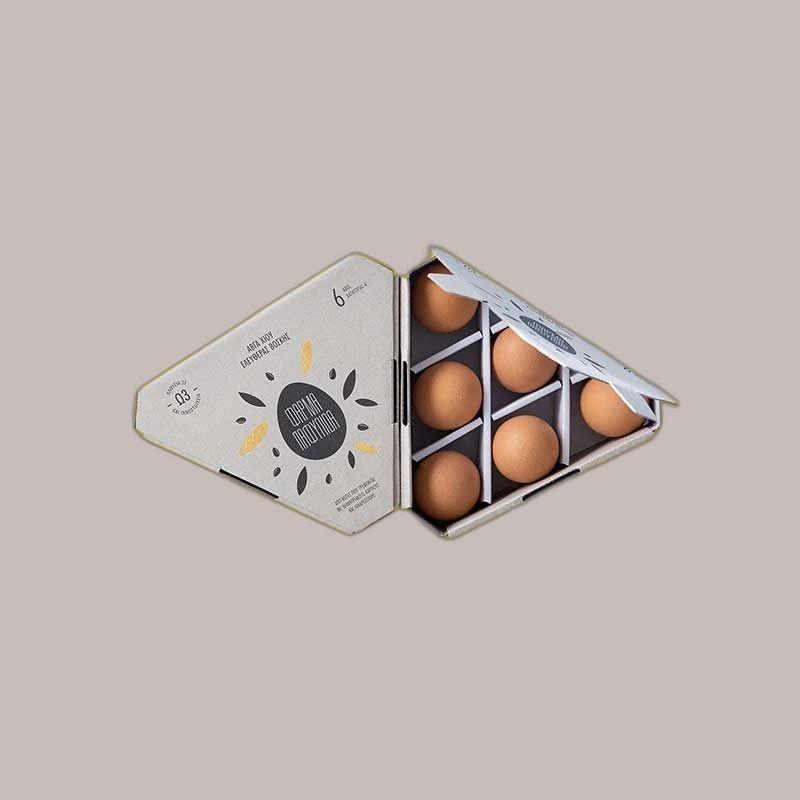

Another good thing about these boxes is that they can be made in almost any size or shape. Get Packaging Services can create boxes that are perfectly sized for your products. This means you don’t have to waste space or use extra packing materials. They can also be printed on with your company’s logo or other information. This helps people recognize your brand and makes your packages look more professional.

How are Corrugated Boxboard Boxes Made?

The process starts with rolls of paper. These rolls are fed into a large machine called a corrugator. The corrugator heats and shapes the paper to create the wavy corrugated medium. Then, the linerboard is glued to the corrugated medium to create the finished boxboard.

Once the boxboard is made, it is cut and folded into the desired shape. Get Packaging Services uses special machines to cut and fold the boxboard accurately. The boxes can be glued, stapled, or taped together. Often, they are shipped flat to save space and then assembled when needed.

Types of Corrugated Boxboard Boxes

There are different kinds of corrugated boxboard boxes. The main difference is the thickness of the boxboard and the type of flute (the wavy part). Thicker boxboard and larger flutes make the box stronger. Single wall boxes have one layer of corrugated medium. Double wall boxes have two layers of corrugated medium, making them even stronger. Get Packaging Services can help you choose the right type of box for your needs, depending on what you’re shipping and how far it’s going.

Regular Slotted Containers (RSC) are the most common type of corrugated boxboard box. They are simple to make and easy to use. Die cut boxes are cut into special shapes and can be used for more specialized packaging needs.

Using Corrugated Boxboard Boxes the Right Way

To get the most out of your corrugated boxboard boxes, it’s important to use them correctly. First, make sure the box is the right size for your product. If the box is too big, your product might move around and get damaged. If the box is too small, it could crush your product.

Second, use packing materials to protect your product. Bubble wrap, packing peanuts, or paper can help cushion your product and prevent it from breaking. Third, seal the box securely with strong tape. Make sure to tape all the seams of the box to prevent it from opening during shipping. Get Packaging Services can provide advice on the best ways to pack your products for safe shipping.

Why Choose Get Packaging Services?

Get Packaging Services provides high quality corrugated boxboard boxes that you can trust. We offer a wide range of sizes and styles to meet your specific needs. We are committed to providing excellent customer service and helping you find the perfect packaging solutions. We also focus on sustainability by using recycled materials whenever possible.

We know how important it is to get your products delivered safely and on time. That’s why we make sure our boxes are strong and reliable. We are here to help you with all your packaging needs, from small businesses to large corporations. Contact Get Packaging Services today to learn more about our corrugated boxboard boxes and other packaging products. We can help you find the right solution for your shipping needs, at a price that fits your budget.

Our turnaround time is 8-10 working days. You may shop with us for as low as just 100 pieces. Moreover, your design customizations will be taken care of by our expert designers. You can consult with them to have the most amazing designs for your

Corrugated Boxes. Our customer service is available 24/7. You can contact us via live chat, send us an email at

sales@getpackagingservices.com or simply call at 773 572 9034 for instant assistance.